Exterior Cladding Panels

Show more

14 products

4320 CLADDING DOUGLAS FIR 28x120 UYS

Arctic OutdoorCLADDINGDOUGLAS FIR 28x120 UYS4320

Out of stock

10

,06

€/m

91

,60

€/m²

4321 CLADDING DOUGLAS FIR 28x145 UYS

Arctic OutdoorCLADDINGDOUGLAS FIR 28x145 UYS4321

Out of stock

11

,88

€/m

88

,00

€/m²

4322 CLADDING DOUGLAS FIR 28x195 UYS

Arctic OutdoorCLADDINGDOUGLAS FIR 28x195 UYS4322

Out of stock

16

,04

€/m

86

,70

€/m²

4467 CLADDING 21 x 95 UTK BEADED UNTREATED

CLADDING21 x 95 UTK BEADED UNTREATED4467

In stock 1,336 m

2

,13

€/m

25

,10

€/m²

4191 CLADDING 23 x 95 UTS UNTREATED

CLADDING23 x 95 UTS UNTREATED4191

In stock 1,373 m

2

,06

€/m

24

,40

€/m²

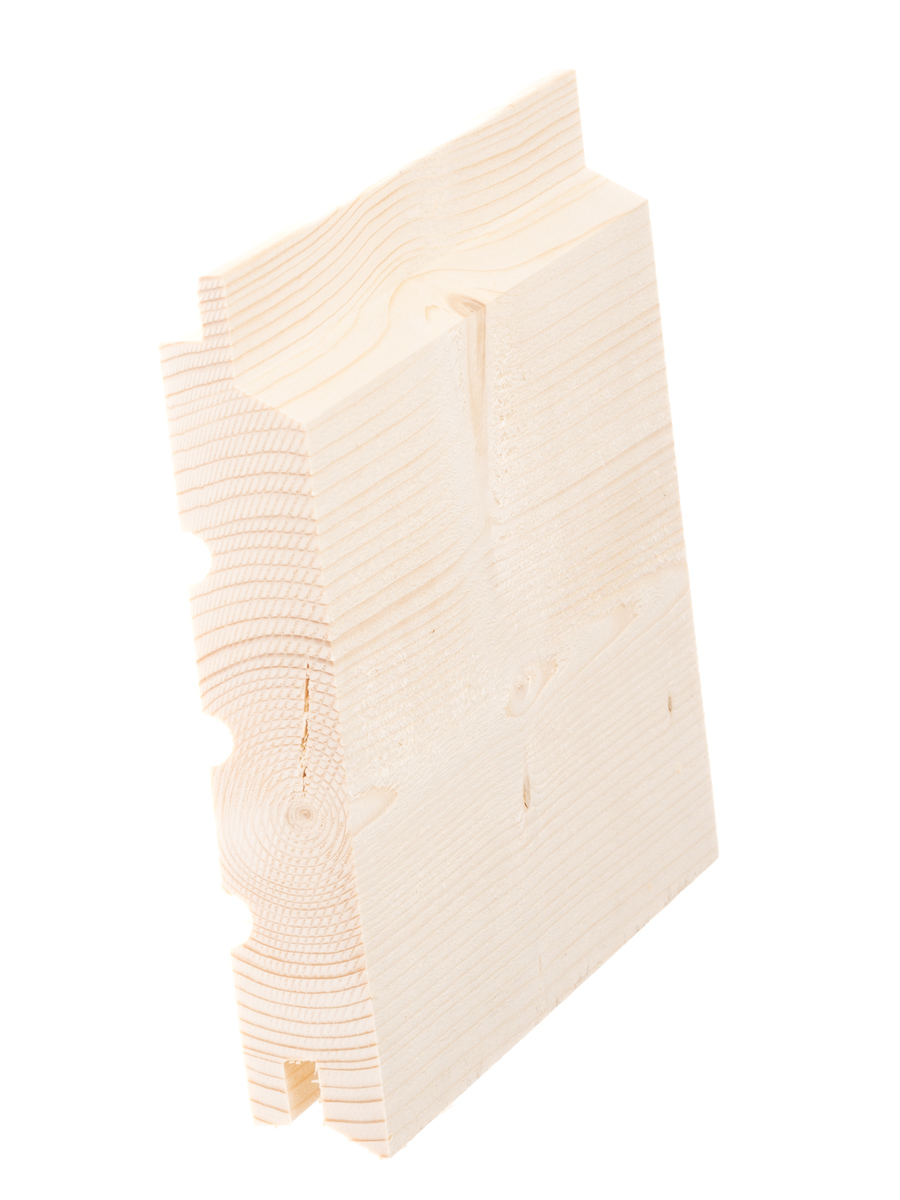

4001 CLADDING 23/10x120 UYL BEVEL CLADDING UNTREATED

Discount

CLADDING23/10x120 UYL BEVEL CLADDING UNTREATED4001

In stock 331 m

2

,47

€/m

3

,09

22

,90

€/m²

28

,70

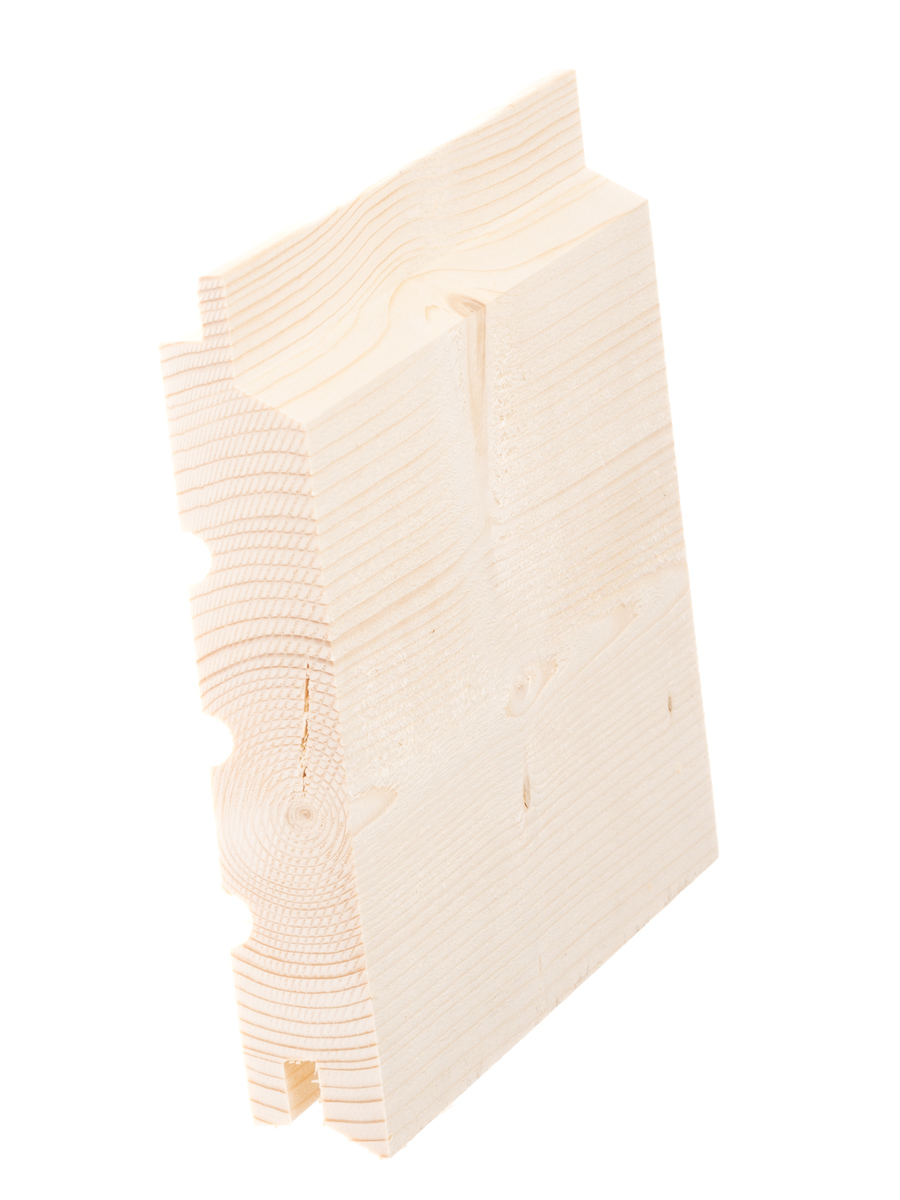

4339 CLADDING FINNISH SPRUCE 23x145 UTS UNTREATED

CLADDINGFINNISH SPRUCE 23x145 UTS UNTREATED4339

In stock 1,186 m

3

,25

€/m

24

,10

€/m²

4352 CLADDING 28x170 UTW UNTREATED

Discount

CLADDING28x170 UTW UNTREATED4352

In stock 2,658 m

4

,86

€/m

5

,40

31

,40

€/m²

34

,90

5025 CLADDING LARCH 23x145 UTV

Discount

Arctic OutdoorCLADDINGLARCH 23x145 UTV5025

In stock 144 m

6

,40

€/m

7

,99

47

,50

€/m²

59

,20

4529 CLADDING LARCH 28 x 95 UYS

Discount

Arctic OutdoorCLADDINGLARCH 28 x 95 UYS4529

In stock 3,573 m

5

,35

€/m

6

,65

63

,20

€/m²

78

,50

4040 CLADDING LARCH 28/15x120 UYL BEVEL CLADDING

Discount

Arctic OutdoorCLADDINGLARCH 28/15x120 UYL BEVEL CLADDING4040

In stock 3,564 m

5

,10

€/m

6

,38

46

,40

€/m²

58

,00

4766 CLADDING LARCH 28x120 UYS

Discount

Arctic OutdoorCLADDINGLARCH 28x120 UYS4766

In stock 2,935 m

6

,70

€/m

8

,37

61

,00

€/m²

76

,20